Imagine this: You’ve got your trusty blender whirring away on a Sunday morning, whipping up a smoothie, when suddenly… snap. The little plastic gear that connects the motor to the blade pops off. In the past, this tiny failure might have driven you to toss your otherwise functional appliance and buy a new one. But thanks to the trailblazing minds at Philips and their new Fixables initiative, you might be able to 3D print that very part at home. Sounds like something out of a sci-fi flick, doesn’t it?

The Birth of Fixables: A Closer Look at Philips’ Vision

Philips, the stalwart of consumer electronics, has launched something quite revolutionary. They’ve dipped their toes into the waters of 3D printing, not by creating new products, but by offering users the opportunity to print replacement parts. This isn’t just a testament to technological innovation; it’s a bold step towards sustainability. Imagine if more companies encouraged such initiatives! Far fewer gadgets would end up in our ever-growing waste dumps, and we’d see a real impact on our collective carbon footprint.

Yet, as promising as it sounds, this initiative doesn’t skate by without its fair share of questions and potential challenges. Who exactly reaps the most benefits here, and what about those who are not particularly tech-savvy? Let’s dive deep into the nuts and bolts of this concept.

The Practicality of DIY Repairs: Real Deal or Pipe Dream?

Sure, 3D printing your own replacement parts sounds groovy, but how practical is it really? First, let’s acknowledge that a 3D printer isn’t exactly a standard household item – yet. Though they’re becoming more affordable, the initial investment still deters many. But if they cross the price threshold for mass household acceptance (much like microwaves did decades ago), the gears could truly start turning.

Envisioning the Setup

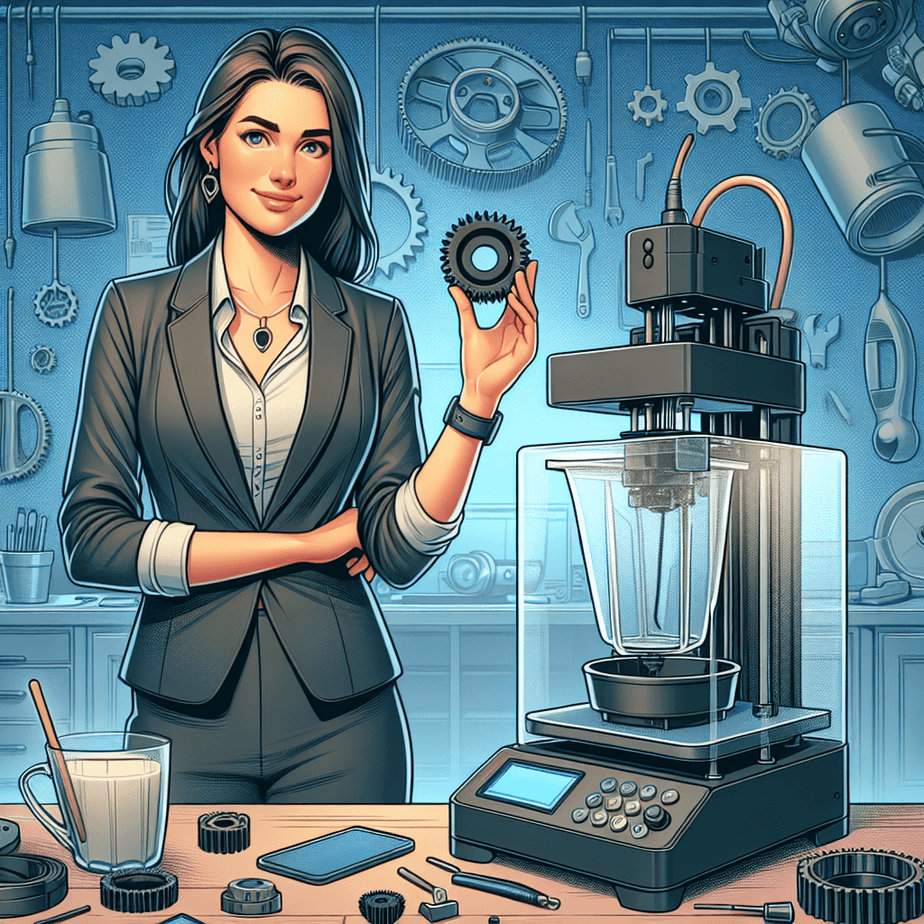

Picture this for a second: a corner in your home designated as the “repair station,” equipped with a sleek 3D printer. You’d also have a digital filing cabinet full of blueprints downloaded from platforms like Philips Fixables. The allure of waving a wand (or printing nozzle, in this case) to fix your faulty gadgets would appeal to many DIY enthusiasts.

However, the question remains: who bears the responsibility of mastering this tech? For the average consumer, the learning curve might look like Everest. The interface would need to be user-friendly, almost as intuitive as, say, assembling IKEA furniture—minus hunting for missing Allen keys.

The User Experience: Not Just for the Tech-Savvy

But let’s face it, not everyone is ready to don a lab coat and become a 3D printing techie just to fix a coffee maker. Philips would need to ensure a seamless, almost foolproof process for those less technically inclined. The user interface should resonate with simplicity akin to using a smartphone – we’re talking drag, drop, and hit ‘print.’ Training and support would play monumental roles here. Workshops or easily digestible online tutorials could really amp up user engagement.

Potential Pitfalls and Safety Concerns

Also, let’s talk safety. Without strict guidelines, a misprinted part could potentially have compatibility issues, quality deficits, or even cause accidents. Philips and other companies exploring this path must consider standards as rigorous as those in toy manufacturing—except you wouldn’t want your blender part melting in the heat of culinary battle.

Early Rollout and Expectations: The Starting Blocks

Let’s sift through what Philips has rolled out and what’s still under wraps. Their current offerings are arguably just the tip of the iceberg. They’ve begun with less complicated components — parts like knobs, buttons, and those small, wear-and-tear pieces. Imagine a bar chart showing slowly rising interest in this service, culminating in a surge once more intricate parts become available.

Annoyingly, what remains unclear is the full list of parts and products that’ll fall under this umbrella. Will it extend beyond Philips’ own gadgets? Will licensing open up for other brands or just remain an in-house luxury? This uncertainty could both tantalize and frustrate potential users looking to convert this app-driven dream into reality.

| Aspect | Current Challenge | Potential Solution |

|---|---|---|

| 3D Printer Availability | High Initial Cost | Community Lending Programs |

| User Accessibility | Complex Learning Curve | Intuitive Software Interfaces |

| Quality Control | Inconsistent Prints | Certified Material Packs |

Long-Term Impact: A Cultural Shift?

If everything goes swimmingly, broadened access to 3D printing could ignite a broad cultural shift in how we view, use, and discard our everyday tech. This isn’t just about technology but a broader movement towards a more responsible consumer lifestyle. So, could this innovation signal the era of ‘repair, don’t replace’? A time when our kids will inherit a world where “the blender broke” means a quick trip to the computer rather than the mall?

Moreover, consider the job market. A rise in 3D printing’s popularity might spawn new industries or revitalize older ones. The demand for 3D design educators, repair specialists, and customer support roles could see a boom. Interestingly, imagine the community impact: DIY spaces or local libraries with shared printers, creating hubs of activity where people come together over common goals – fixing and learning.

Riding the Wave of New Beginnings

But, how effectively can other companies follow Philips’ lead? Corporations like Samsung, Panasonic, and even non-tech brands could jump on this bandwagon. Beyond electronic gadgets, think shoes, household fixtures, even furniture. The more industries that join this initiative, the bigger the splash in the ocean of consumer goods. Without a doubt, a rise in consumer empowerment would redefine the purchasing dialogue from “Should I buy it new?” to “Can I fix it myself?”

Visualize a line graph showing early adopters smiling brightly as their repair costs nosedive while their satisfaction rates skyrocket. Those numbers could really turn heads, perhaps even coax a tech-giant or two into giving 3D printing a whirl.

Closing Thoughts and a Call to Arms

In conclusion, Philips treading into the 3D printing realm is more than just a business maneuver. It’s a call to action for us as consumers, designers, and businesses to embark on something future-focused and substantial. To truly embrace this shift, though, the tech has to be accessible, affordable, and intuitive.

As this initiative evolves, here’s hoping that more companies hop on board, spurring a tidal wave of change. As remote as the prospect might seem now, it’s high time we transformed “fixing” from a tedious chore into a transformative experience. Dive in, explore, and who knows? You might find you’ll become a repair wizard, one printed part at a time.